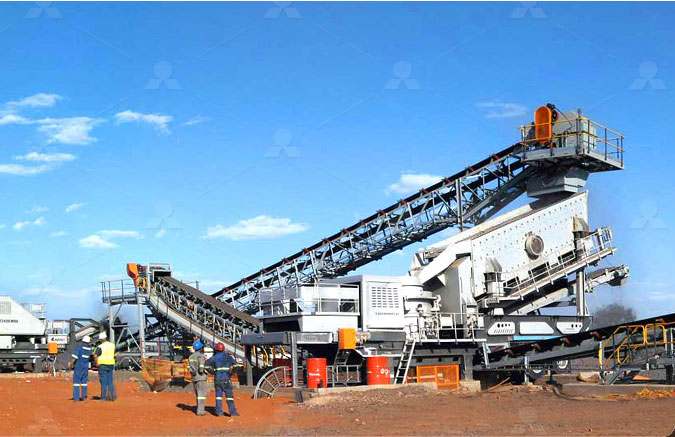

How Much is a Mobile Jaw Crusher with 200 TPH?

Are you looking for a reliable and efficient mobile jaw crusher that can handle up to 200 tons per hour? If so, you’ve come to the right place. In this comprehensive guide, we’ll explore everything you need to know about this powerful mining equipment, including its working principles, applications, technical specifications, and more. Whether you’re a mining professional or an entrepreneur looking to expand your operations, understanding the capabilities and cost of a 200 TPH mobile jaw crusher will be crucial for your success.

-

- European Standard High Quality Aggregate Crushing

- NK Mobile Crusher: Versatile Crushing Solution

- Plant Health and Safety

What Is a Mobile Jaw Crusher?

A mobile jaw crusher is a type of compact crushing machine designed for versatility and efficiency in various mining and construction operations. It combines the functionality of a jaw crusher with a tracked or wheeled mobile platform, allowing it to move from one location to another with ease. This makes it an ideal choice for projects that require flexibility and quick setup.

The jaw crusher is a fundamental piece of equipment in any rock crushing or material reduction operation. It consists of two movable jaw plates that compress the material between them, creating a crushable particle shape. The fixed jaw plate acts as the counterweight, while the movable jaw plate adjusts to create the desired particle size. When paired with a mobile platform, this equipment can be deployed on construction sites, quarries, or mining complexes, providing a cost-effective solution for processing large volumes of material.

-

How Does a Mobile Jaw Crusher Work?

The operation of a mobile jaw crusher is straightforward and efficient. Here’s a step-by-step breakdown of how it works:

1. Feeding the Material: The material to be crushed is fed into the jaw crusher through a hopper. The material’s size is determined by the settings of the jaw plates, which can be adjusted to control the final particle size.

2. Compression and Crushing: As the movable jaw plate moves inward, it compresses the material between the fixed and movable plates. This compression forces the material to break apart, creating smaller particles.

3. Discharge of Crushed Material: The crushed material is discharged from the crusher through a conveyor belt or tracked platform, which is connected to the mobile unit.

4. Adjustments and Maintenance: Operators can adjust the jaw plates, toggle the release mechanism, or perform maintenance on the crusher to ensure optimal performance and longevity.

The mobile nature of this equipment allows it to move to different locations without the need for additional setup or dismantling, making it ideal for construction sites, quarries, and mining complexes.

-

Applications of a Mobile Jaw Crusher

Mobile jaw crushers are widely used in various industries, including:

1. Mining Industry: These crushers are essential for processing rock and ore in open-pit and underground mines. They can handle large volumes of material, making them ideal for ore extraction and processing.

2. Construction and demolition (C&D) Recycling: Mobile jaw crushers are commonly used to recycle construction debris, reducing waste and promoting sustainability. The equipment can handle materials like concrete, brick, and stone, breaking them down into smaller, manageable pieces.

3. Aggregate Production: In Quarries and aggregate operations, mobile jaw crushers are used to produce clean, graded stone and gravel, which are essential for road construction and other infrastructure projects.

4. Contract Mining and Crushing: These crushers are versatile enough to handle a wide range of materials, including hard rock, soft rock, and even some types of stone and mud.

The versatility of mobile jaw crushers makes them a valuable asset for any operation that requires efficient material processing.

-

Technical Specifications of a 200 TPH Mobile Jaw Crusher

When considering a mobile jaw crusher with a capacity of 200 tons per hour, it’s important to understand its technical specifications:

1. Crusher Capacity: The primary function of a mobile jaw crusher is to process material at a high rate. A 200 TPH capacity indicates that it can handle a substantial volume of material, making it suitable for large-scale operations.

2. Jaw Plate Size: The size of the jaw plates determines the maximum particle size of the material that can be processed. Typically, these crushers are designed to handle materials up to 1000mm x 600mm.

3. Adjustable Jaw Settings: The adjustable jaw plates allow operators to control the final particle size, ensuring that the crushed material meets the specific requirements of the application.

4. Tracking and Stability: Modern mobile jaw crushers are equipped with tracked or wheeled platforms for enhanced stability and durability, especially on uneven or rough terrain.

5. Hydraulic and Electrical Systems: These systems are essential for controlling the crusher’s operations, including the movement of the jaw plates, adjustment of settings, and monitoring of performance.

6. Noise and Vibrations: Mobile jaw crushers are designed with noise reduction features and vibration dampening systems to minimize operational noise and vibrations, ensuring a safe and efficient working environment.

7. Maintenance and Lifespan: Proper maintenance schedules and the use of high-quality components can extend the lifespan of the crusher, reducing downtime and operational costs.

-

Choosing the Right Mobile Jaw Crusher

When selecting a mobile jaw crusher with a capacity of 200 TPH, it’s important to consider several factors:

1. Material Type: Ensure the crusher can handle the specific type of material you’re processing, such as hard rock, ore, or construction debris.

2. Capacity Requirements: Verify that the crusher’s capacity of 200 TPH meets your operational needs.

3. Performance and Reliability: Look for reviews and ratings from other users to gauge the crusher’s performance, reliability, and durability.

4. Weight and Size: Consider the weight and size of the crusher to ensure it can be transported and deployed efficiently on your site.

5. Cost: Balance the initial investment with long-term operational costs, including parts and maintenance.

6. Support and Service: Ensure that the supplier provides reliable support and service, including spare parts and technical assistance.

-

Frequently Asked Questions About Mobile Jaw Crushers

1. What is the typical working hours of a mobile jaw crusher?

- Mobile jaw crushers are designed to operate for extended periods, often running for 8-12 hours or more, depending on the application.

2. Is a mobile jaw crusher suitable for small-scale operations?

- Yes, small-scale operations can benefit from mobile jaw crushers, as they offer flexibility and cost-effectiveness. However, their capacity may be limited to smaller volumes.

3. Can a mobile jaw crusher handle sticky or abrasive materials?

- Some mobile jaw crushers are equipped with features like moisture screens or tertiary crushers to handle sticky or abrasive materials effectively.

4. What is the typical maintenance schedule for a mobile jaw crusher?

- Maintenance schedules vary depending on the equipment and usage. Regular checks of wear parts, lubrication, and alignment are essential for optimal performance.

5. Are mobile jaw crushers energy-efficient?

- Modern mobile jaw crushers are designed with energy-efficient technologies to minimize energy consumption while maintaining high production rates.

-

Conclusion

A mobile jaw crusher with a capacity of 200 TPH is a powerful and versatile piece of equipment that can handle a wide range of applications in mining, construction, and demolition. Its compact design, adjustable settings, and high production rate make it an ideal choice for both large-scale operations and small-scale projects. When selecting a mobile jaw crusher, it’s important to consider its technical specifications, material compatibility, and overall cost-effectiveness. With the right equipment, you can efficiently process materials, reduce operational costs, and achieve your production goals. Whether you’re a mining professional or an entrepreneur, a mobile jaw crusher is a valuable asset for your operations.